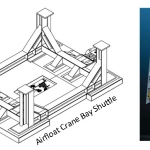

Airfloat applies air bearing (or “air caster”) technology and innovative design to move and position anything from a 200-ton locomotive to placing a pallet or basket of parts at the ergonomically-correct position along your assembly line. Airfloat solves problems in your workspace with devices that increase your efficiency with easier, faster, and safer material movement.

| A History of Engineering and Innovation |

|

| An F-15 rests on Airfloat assembly transporters circa 1985. |

Airfloat was founded in 1967 with a focus on providing engineering solutions through air bearings technologies. The original air caster development took place at GM by an engineering group that experimented with the friction-free results of movement with air. The original use, which remains a very prominent use, was to move heavy loads within plant operations. When GM developed a loss of focus on the mass-market appeal of the air casters, a GM engineer by the name of David Snoeyenbos secured the rights to the technology and started Airfloat in Decatur, Illinois.

Today Airfloat continues to operate and manufacture air bearing and material handling solutions at the Decatur corporate facility. Sales are both domestic and international.